When you think of a car racing parts business, you think of large corporations with multiple numbers, multiple sponsors and multiple partnerships with other companies to sell their products to the consumer. When you do a Google search you’ll find plenty of locations around the world that have mediocre customer service where most of the the products are not of the highest quality.

On the contrary, Anthony Woodford Racing’s (AWR) customer service is top notch with products to back you up. They also respond within the hour of you asking a basic question or for help via email if you decide not to give them a call first.

The average car enthusiast, and DIY (do it yourself) person will spend hours on forums. Searching for their specific make and model in an attempt to troubleshoot problems their car may be experiencing or simply to just chat with their community.

Companies make specific products for specific vehicles that are far more advanced and researched than your average car parts company. These aftermarket products potentially help your car be a better version of itself. This is the case for AWR, a small mom-and-pop shop located in Vista, Calif.

This is where Tony Woodford and his wife Sheree, daughter Ali and son Colin work together to produce fabricated aftermarket parts for specific Ford and Mazda makes and models. Models that are widely used in modern-day racing such as Mazda RX-7 and RX-8 that use a rotary style engine, Ford Focus ST and Ford Fiesta ST. Who could forget the almighty Mazda Miata MX-5, one of the most popular models for aftermarket modifications because they are very forgiving.

A part of a car designed and built at Anthony Woodford Racing (AWR). (Park Meister/IMPACT Magazine)

What AWR offers is an incomparable custom prototyping and race car engineering and restoration service to automotive manufacturers, racers and collectors alike and it is hard to believe that all of this is possible and managed with just four people. A small office gives the illusion of being a huge car company because it is so widely known throughout the country and the world.

Online forums have nothing but great things to say. Tony Woodford learned his craft from an old-world master, from restoring vintage sports cars, to building one of the prototypes that formed compound curves, molded fiberglass, carbon and redesigned vintage racers to compete against technologically advanced models. Tony developed technical expertise and meticulous fabrication skills that would be sought after by Premier Auto Racing operations and enthusiasts.

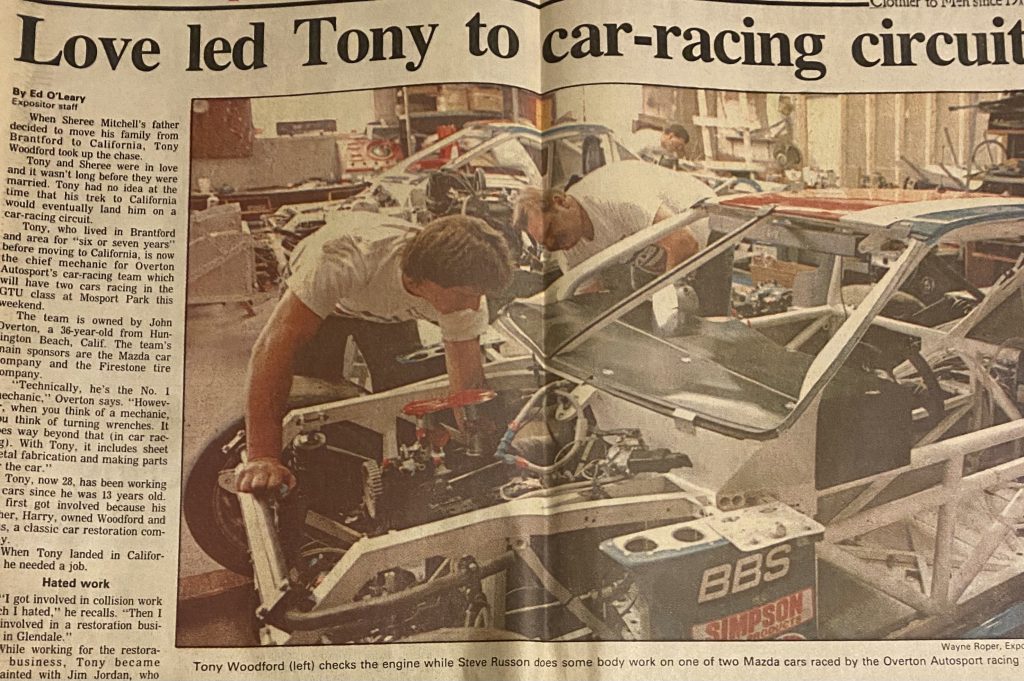

In 1986, Tony focused on the auto-racing field, joining various Sports Car Club of America (SCCA) racing teams, including Overton Autosport – an International Motorsports Association (IMSA) Grand Touring team from 1989 to 1993. Tony worked with Nissan performance technology which dealt a successful Certified Training Personel Team, with drivers such as Chip Robinson. This was followed by heavy involvement with Formula Atlantic Professional Teams.

Tony founded AWR in 1995 and quickly developed a relationship with Mazda competition parts, a division of Mazda USA developing various parts for the Grassroots Racing Industry, event design and prototype: a rotary-powered Formula Atlantic race car. The rotary-powered Formula Atlantic race car breeds a powerful and efficient rotary solution to compete with Toyota power plants.

To date, nine rotary-powered Atlantic cars are campaigning in the Sports Car Club of America. AWR is currently concentrating its growth on advanced suspension design and exhaust system technology.

Under Tony’s watchful eye, and uncompromising standards, the Formula Atlantic Project will be pushed to the next level. Meanwhile, Grassroots development continues to evolve with products for touring and GT race teams, and formula one projects are expanding as well.

AWR met with Mazda to discuss retrofitting a new MX-5 with a roll cage and race-trim. This MX-5 was introduced to the world and promoted to the new MX-5 Cup Series. They were designated to participate as an active vendor and supplier in the series for several years.

Tony Woodford was in a photo of a feature story in a Canadian newspaper in 1986. (Parker Meister/IMPACT Magazine)

Racing Cages, Inc. was the sister company and Tony along with his wife Sheree started AWR. Tony built roll cages for Spec Miatas, MX-5 Cup Series, and a large number of cages for Skip Barber Racing School.

Amidst the COVID-19 pandemic, other businesses had no other choice to close shop, AWR had a very inverse outcome and getting more business then actually having business slow down. With people potentially forced to stay at home, this gave a lot of people some time to catch up on personal endeavors. These endeavors included car repairs, and AWR orders got a boost in business with people having all this free time due to the stay-at-home order issued by the government.WR does not pay for advertising because their advertising is through word of mouth. This is due to Tony’s many years of mechanic and fabrication work with race teams. He has built quite a reputation for his astounding work from one man, that he was granted in 1998 the SCCA Mechanic Of The Year Award which is an extremely high feature for someone to achieve and speak volumes.

Greg Mishimoto, a San Diego resident and DIYer shared his experience with AWR: “Reason why I decided to go with AWR Racing is because the stock transmission mount design is extremely sketchy and made me worry it would fail again! It has a single bolt that goes vertically and holds everything together and if you are not careful with that bolt like I was I accidentally stripped the threads, which caused the transmission to fall out one day while I was driving my car and it was nerve wrecking! So I did not want to deal with that and saw AWR’s transmission mount design and how simple and better designed it was and offered even a soft durometer bushing as an option.”

Mishimoto continued, “So I got in contact with Ali. She hooked me up and I went up to AWR HQ. Ali gave me a cool shop tour and I met the crew and saw the many car projects. I did not know everything was created and fabricated ‘in-house’ which was awesome as well! After installing the transmission and passenger mounts I was amused by how awesome my car felt and the first start-up and driving around. It handled incredibly well on the freeway now! Smooth idle when waiting at a stoplights, overall satisfied customer. I had a few technical issues when installing the transmission mount but, Ali was there to help me out when I had a ton of questions.”

A prototype frame of a race car by Anthony Woodford Racing (AWR). (Parker Meister/IMPACT Magazine)

Marlon Sumlin, who is a part of a small racing team in Parma, Ohio, known as Force Racing had nothing but great insight on AWR when asked about his experience when doing business with AWR.

“First and foremost, price does not matter to us! You can have a lower price, but if your customer service is not up to par, you have lost a customer,” Sumlin said. “Ali Woodford and AWR have been on point for customer service since we have Mazdas for over 17 years. You order a product, you get great follow-up service, tracking number, and shipping updates via email. The products are all of the highest quality and AWR stands behind them! From our Mazdaspeed 3, MSP, Mazda 6s to our Mazda 2! AWRis a part of each of cars and we are proud to be part of team AWR!”

If your automotive project demands precision engineering and old world craftsmanship, you’ll find an expert resource in AWR.

Tony Woodford (second from left) and his family. (Parker Meister/IMPACT Magazine)

Recent Comments